2-WAY BALL VALVE DUAL BLOCK®

FIP has developed a VKD DUAL BLOCK® type ball valve to introduce a high reference standard in the design of thermoplastic valves.

CHARACTERISTICS COMMON TO ALL VKDs:

- Jointing system by gluing (only PVC-U and PVC-C for DN 10:50 and implemented DN 65:100), by welding (only PP-H and PVDF for DN 10:50 and implemented DN 65: 100), for threading and for flanging

- SEAT STOP® patented ball support system, which allows for micro-adjustment of the seals and minimization of the effect of axial thrusts

- Easy radial disassembly from the system and consequent rapid replacement of O-Rings and ball seals without the use of any tools

- Valve body (PN 16 for VKD DN 65:100) with radial disassembly (True union) made by injection molding in PVC-U, PVC-C, PVDF, PP-H equipped with integrated drilling for actuation. Test requirements according to ISO 9393

- Possibility of disassembling the downstream piping with the valve in the closed position

- Floating type full bore ball with high surface finish

- Support integrated in the body for fixing the valve

Manual valves

SPECIFIC CHARACTERISTICS VKD MANUAL DN 10:50:

- Ergonomic multifunction handle in HIPVC equipped with removable key for adjusting the support of the ball seals

- Handle block 0°- 90° SHKD (available as an accessory) ergonomically operable during the maneuver and padlockable

- Sturdy anchor turret for easy and rapid automation even after the valve has been installed on the system using the Power Quick module (optional)

- Patented DUAL BLOCK® locking system of the ring nuts which ensures the tightness of the ring nut even in the case of harsh conditions such as in the presence of vibrations or thermal expansion

- Machined ball with high surface finish that guarantees excellent maneuverability and greater reliability

- The adjustment of the ball support can be done using the Easytorque adjustment kit

- Possibility of having a handle with an integrated LSQT limit switch box, also for retrofitting existing installations

- Compatibility of the valve material (C-PVC only) and of the elastomer sealing elements (EPDM or FKM), with the conveyance of water, drinking water and other food substances according to the regulations in force

SPECIFIC CHARACTERISTICS VKD MANUAL DN 65:100:

- Ergonomic multifunction handle in HIPVC with the possibility of rapid manoeuvring, locking and graduated adjustment in 10 positions. Possibility of inhibiting rotation by placing a padlock

- Personalization system Labeling System: LCE module integrated in the hub made up of a transparent protective cap and a label holder customizable using the LSE set (available as an accessory). The possibility of customization allows you to identify the valve on the system according to specific needs

- Patented DUAL BLOCK® locking system of the ring nuts which ensures tightness of the ring nut tightening even in the case of harsh conditions such as in the presence of vibrations or thermal expansion

- Double stem with double O-Rings for ball centering and reduction of operating torques

- Machined ball with high surface finish that guarantees excellent maneuverability and greater reliability

- Possibility of installing a manual reducer or pneumatic and/or electric actuators by applying a PP-GR flange with ISO standard drilling

- STAINLESS steel drowned stem, square section in accordance with ISO 5211 standard.

- Possibility of having a handle with an integrated LSQT limit switch box, also for retrofitting existing installations

- Compatibility of the valve material (C-PVC only) and of the elastomer sealing elements (EPDM or FKM), with the conveyance of water, drinking water and other food substances according to the regulations in force

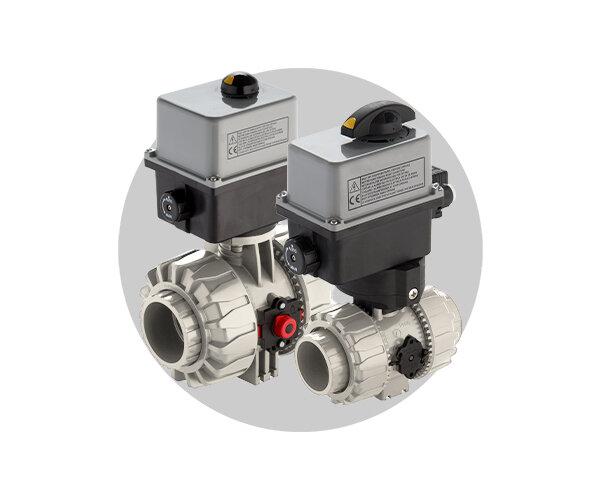

Valves actuated

VKD SPECIFIC CHARACTERISTICS IMPLEMENTED DN 10:50:

- The adjustment of the ball support can be done using the Easytorque adjustment kit

- Electric actuator made on FIP specifications; with shells in plastic material and manual emergency control as standard. Available in voltages from 12 to 240V

- Rack & pinion type pneumatic actuator made to FIP specifications; fully protected against corrosion by atmospheric agents available in double acting (DA) or single acting version normally closed (NC) or normally open (NO)

- Stem with high surface fi nish with double sealing o-ring. The double key connection system guarantees a robust and reliable transmission of the actuator torque to the ball

- PowerQuick module for pneumatic or electric actuation made entirely of highly robust and easy to install technopolymer

- Patented DUAL BLOCK® locking system of the ring nuts which ensures tightness of the ring nut tightening even in the case of harsh conditions such as in the presence of vibrations or thermal expansion

- Fixing base integrated in the valve body with stainless steel threaded inserts to firmly anchor the valve to a support

VKD SPECIFIC CHARACTERISTICS IMPLEMENTED DN 65:100:

- Possibility of installing a manual reducer or pneumatic and/or electric actuators by applying a PP-GR flange with ISO standard drilling

- STAINLESS steel drowned stem, square section in accordance with ISO 5211 standard

- Electric actuator made to FIP specifications, with shells in plastic material and manual emergency control as standard. Available in voltages from 12 to 240V

- Rack & pinion type pneumatic actuator made to FIP specifications; fully protected against corrosion from atmospheric agents available in double effect (DA) or single effect normally closed (NC) or normally open (NO) version

- Patented DUAL BLOCK® locking system of the ring nuts which ensures tightness of the ring nut tightening even in the case of harsh conditions such as in the presence of vibrations or thermal expansion

- Double stem with double O-Rings for ball centering and reduction of operating torques. The upper rod is also equipped with a co-moulded steel insert which guarantees high strength and perfect torque transmission between actuator and ball

Electrically actuated valves

Pneumatically actuated valves

Contact our product expert