Butterfly valves

The FK is a shut-off and regulation butterfly valve, with structural characteristics that are ideal for use in industrial applications that require high performance and reliability over time. This valve is also equipped with the customized Labeling System.

FEATURES COMMON TO ALL FKs:

- Disc in PVC-U, PVC-C, PVDF or PP-H with interchangeable through shaft in different thermoplastic materials: PVC-U, PVC-C, PVDF, PP-H, ABS

- Overall dimensions of the valve in accordance with ISO 5752 (DN 40÷200 Medium serie25, DN 250÷ 300 Long Serie16) and DIN 3202 K2 and ISO 5752 (DN DN 65÷200 K2, DN 250÷300 K3)

- Can also be installed as an end-of-line valve or bottom drain or quick tank drain

- Special annular version Lug PN 10 with complete drilling DIN 2501 or ANSI B16.5 cl.150 with threaded inserts in AISI 316 stainless steel hot dipped

- Possibility of installing manual reducer or pneumatic and/or electric actuators by applying ISO standard drilling PP-GR flanges. Valve DN 40÷200 equipped with plate with rack in PP-GR. For motorized versions flange with drilling according to ISO 5211 F05, F07, F10.

- Possibility of having a handle with an integrated LSQT limit switch box, also for retrofitting existing installations

- Square section stainless steel stem completely isolated from the fluid

- Body in polypropylene-based compound reinforced with glass fiber (PP-GR) resistant to UV rays and characterized by high mechanical resistance

- Drilling system with oval slots that allows coupling with flanges according to numerous international standards. The special ABS self-centring lunettes supplied for DN 40÷200 ensure correct axial alignment of the valve during installation. For DN 250÷400 the drilling system for self-centering is of the traditional type according to DIN and ANSI standards

- Interchangeable primary gasket with dual function of hydraulic seal and body insulation from the fluid

Manual valves

SPECIFIC CHARACTERISTICS FK MANUAL DN 40:400 PVC-U, PVDF and PP-H DN 40:300 PVC-C:

- Compatibility of the valve material (PVC-U + EPDM) with the conveyance of water, drinking water and other food substances according to the regulations in force

- Valve DN 250÷400 equipped with monobloc turret in PP-GR with high mechanical resistance with mounting flange for operating elements with drilling according to ISO 5211 F10 standard (except DN 350÷400), F12, F14

- Ergonomic handle in HIPVC equipped with a locking, unlocking, rapid maneuvering device and graduated adjustment in 10 intermediate positions (DN 40÷200). The operating range, starting from the first degrees of valve opening, also guarantees extremely low pressure drop values

- Personalization system Labeling System: module integrated in the handle, consisting of a transparent protective cap and a label holder plate that can be customized using the LSE set (available as an accessory). The possibility of customization allows you to identify the valve on the system according to specific needs

- STAINLESS steel stem completely isolated from the fluid with square section according to ISO 5211: DN 40÷65: 11 mm DN 80÷100: 14 mm DN 125÷150: 17 mm DN 200: 22 mm DN 250÷400: 27 mm

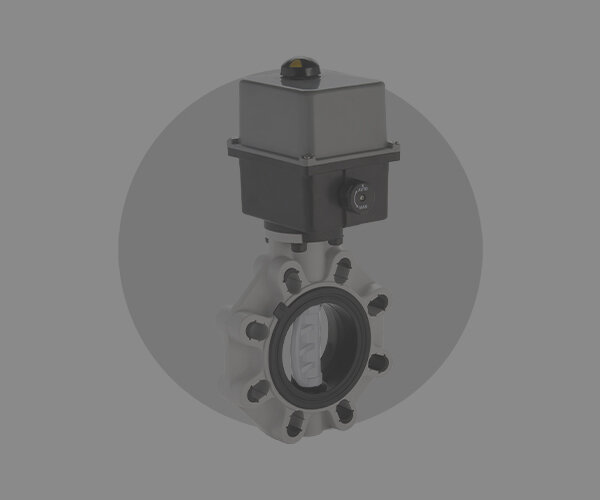

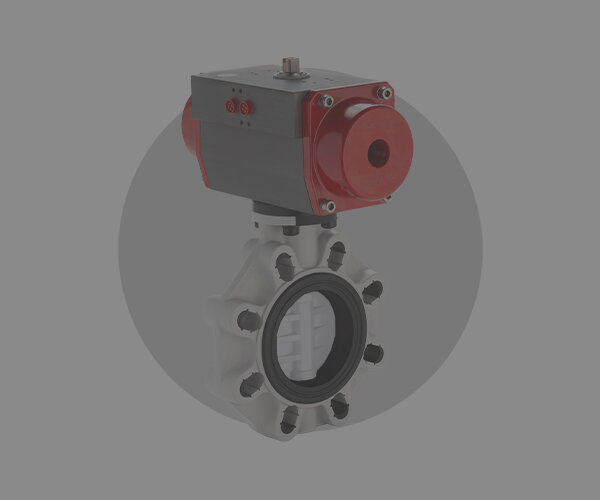

Valves actuated

SPECIFIC CHARACTERISTICS FK IMPLEMENTED DN 40:400:

- Compatibility of the valve material with the conveyance of water, drinking water and other food substances according to the regulations in force

- DN 250÷400 valve equipped with monobloc turret in PP-GR with high mechanical resistance with mounting flange for operating elements with drilling according to ISO 5211 F10 standard (except DN 350÷400), F12, F14.

- Electric actuator made on FIP specifications; with shells in plastic material and manual emergency control as standard. Available in voltages from 12 to 240V.

- Rack & pinion type pneumatic actuator made to FIP specifications; fully protected against corrosion from atmospheric agents available in double effect (DA) or single effect normally closed (NC) or normally open (NO) version.

Electrically actuated valves

Pneumatically actuated valves

Contact our product expert