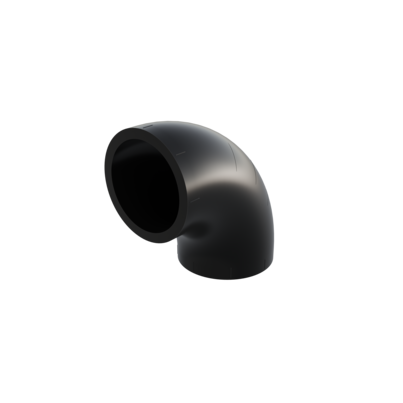

With the new FIP brand PE100-RC fittings we make installation even easier, faster and safer for our customers.

The PE (polyethylene) range is suitable for the make of piping systems used for various applications. These solutions offer excellent performance at temperatures ranging from -40°C to 60°C and feature homogeneous welded joints that can withstand heavy loads.

The offer is completed by:

- the new range of electrofusion fittings, which guarantee reliable, safe, and standardized joints

- the full range of PVC valves with PE connection

- the wide range of fittings manufactured upon request

The PE100 pressure piping system is flexible, robust, and impact-resistant, making it suitable for a wide variety of industrial processes and environmental conditions.

Due to its high strength, PE100 is increasingly used for the assembly of pipe networks, especially where high-pressure is expected. Applications for PE100 systems range from water cooling processes to underground fire extinguishing pipelines.

Among the most important, we find:

- Conveyor systems for industrial processes

- Transportation of solid materials

- Water treatment plants

- Wastewater transportation

- Swimming pool water treatment and recirculation plants

Installation Advantages

Simplified Installation:

- Longer spigot grants a better and easier clamping with current butt-welding machine, and gives the possibility of carrying out an Infra-Red welding too

- Constant thickness along all the fitting length and marks at 30°, 45°, 60° to meet custom installation needs

- 8 orientation lines on the spigots to support performing a correct welding

Same Face-to-Face:

- No changes on face-to-face dimension from d32 up to d110 compared to previous bends to avoid skid design updates nor packaging variation; d20 and d25 have a slight variation in face-to-face dimensions (7 mm and 5 mm respectively)

High-Quality:

- Wide range of certifications and approvals, the new fittings made of PE 100-RC have been also verified and registered for potable water suitability according to DVGW guideline KTW-BWGL

- Best quality resin to ensure optimal performance, in terms of chemical resistance and mechanical behavior. The entire range is made of PE 100-RC. In details, PE-RC combines in a single product increased characteristics of resistance to slow propagation of cracks due to point loads or surface incisions

- Smooth internal surface to minimize impurities sedimentation

Customized solutions:

Aliaxis offer is also including a full range of customized solutions such as wall ducts, seamless bends for butt welding and electrofusion as well as segmented fittings to cope with the several different needs of installation.

Wide areas of application of GKE PE bends:

- Swimming pool

- Industrial water treatment (wastewater)

- Municipal water treatment (wastewater)

- Aquariums & Life Sciences

- Irrigation systems and agriculture

- Shipbuilding

Wide range of certified products

The current PE100-RC range offers a range from d20 up to d110 SDR 11 and SDR 17/17.6.

The production of PE fittings is carried out according to the highest quality standards, all applicable environmental regulations and laws are complied with in accordance with ISO 14001. All products are manufactured according to the ISO 9001 quality system.

The entire range boasts numerous international approvals and is suitable for various specific applications, including use in the drinking water sector.

The several certificates are available for viewing and downloading in the Download area of our home page.

Easy, fast, and safe installation with the new GKE bends

Do you need to make a flanged connection?

Try the innovative 3+ Backing Ring designed by Aliaxis with an optimized design that combines a unique lightness with exceptional mechanical strength, ensuring a simple, safe and reliable installation.

This product is EPD verified because it has a lower environmental impact, reflecting and respecting Aliaxis sustainability goals.

Discover all teh advantages of teh new 3+ Backing rings, click on the link below!

Download

Contact our industry expert

get_app

get_app