Pipes and POWER-LOCK® Bends in PVC-A

The sustainable and innovative solution for water transport, simple and quick to install, reliable and safe without the need of maintenance.

PVC-A Characteristics

PVC-A refers to a polymer alloy that originated in 1995 through collaboration between the English organization North West Water and the research institute Pipeline Development Ltd.

This innovative polymer alloy (PVC-A), combines the strength of PVC-U (unplasticized polyvinyl chloride) with the flexibility of polyethylene (PE). By carefully selecting and blending these materials, we created a new generation of polymer alloy that meets the needs of water industry.

The combination of polyethylene’s ductility and robustness with PVC-U’s high strength results in a new product with excellent performance characteristics, offering both toughness and durability.

Their high-resistance to breakage, even under point loads, combined with a high yield strength, ensures superior performance compared to other plastic materials available in the market

The advantages of the VDA® system

- Resistant to crack propagation: The main cause of breakage during installation and laying operations.

- Maximized flow rate: Reduced pressure drop, and optimized plant management costs thanks to the larger internal diameter compared to other pipes with the same PN.

- Simple and fast installation: Greater maneuverability and safety on-site due to the reduced weight compared to other pipes of the same diameter and PN. Reduced installation times and costs thanks to the quick and reliable jointing technology.

- Guaranteed hydraulic seal: FORSHEDA POWER-LOCK® gasket pre-inserted during the tube flaring phase when hot.

- Corrosion-resistant: No risk of leakage along the network compared to traditional metal pipes.

The VDA® system: pipes and curves in PVC-A for water transport

Our system of PVC-A Pipes and Curves has been designed to provide optimal performance for pressurized water transport, creating a highly durable product suitable for all installation and laying operations.

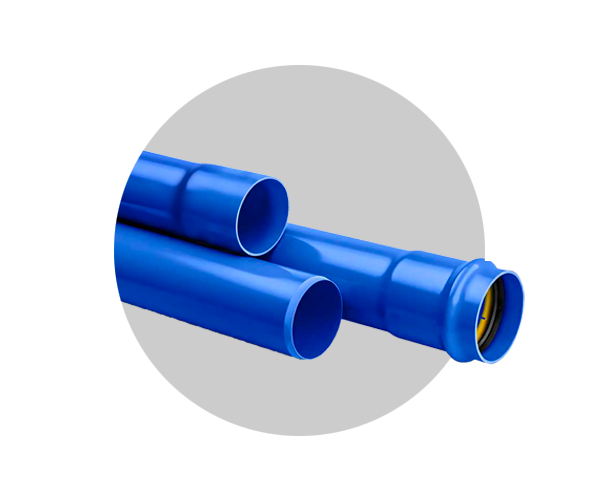

ISO-UNI pipes in PVC-A

VDA® pressure pipe

Our PVC-A Pipes and Curves are designed for pressurized water transport, with joint systems for gluing, threading, and snap-in connections using the FORSHEDA POWER-LOCK® junction.

Available within the range:

- d50 - d500

- PN8 - PN10 - PN12.5 - PN16 - PN20

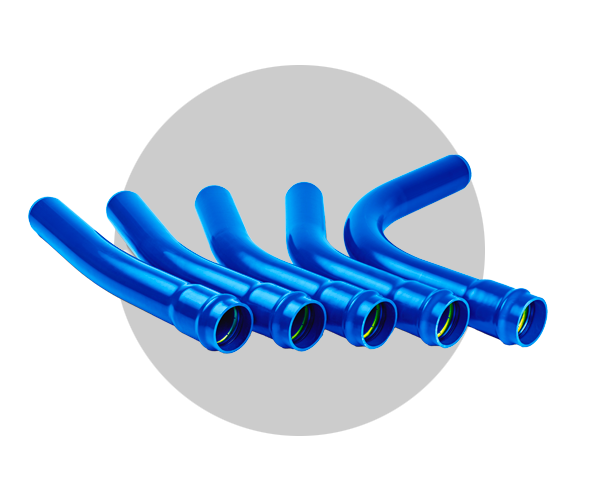

FORSHEDA POWER-LOCK bends

Available within the range:

- ø est. 63-400 mm

- 11° - 22° - 30° - 45° 90°

- PN6 - PN10 - PN16

Regulatory references

Our PVC-A range is produced at Lareter’s headquarters in Fiesso Umbertiano (Rovigo, Italy). Lareter is a company certified with UNI EN ISO 9001 (Quality certification issued by IIP – Italian Institute of Plastics), UNI EN ISO 14001 (Environmental certification issued by BSI – British Standards Institution), and ISO 45001 (Occupational health and safety management system certification issued by BSI – British Standards Institution).

- BS PAS 27: 1999 unplasticized polyvinyl chloride alloy pipes and bends

- PVC-A under pressure

- Certified potability according to D.M. n° 174 / 2004

- UNI EN 1622 - Smell and taste threshold

Approvals and quality brands

KIWA (Keurings Institut Voor Waterleiding Artikelen Holland) KQ KIWA QUALITY KIP-105133 Standard that fully implements BS PAS 27:1999

ACS The VDA® system is certified suitable for coming into contact with water intended for human consumption according to the Attestation de conformité sanitaire (ACS).

EPD HUB - 1 Feb 2022 EN 16904 Product Category Rules (PCR) per sistemi di tubazioni plastiche interne. HUB-1151, Environmental product declaration In accordo a EN 15804+A2 & ISO 14025

Download

Contact our industry expert

get_app

get_app