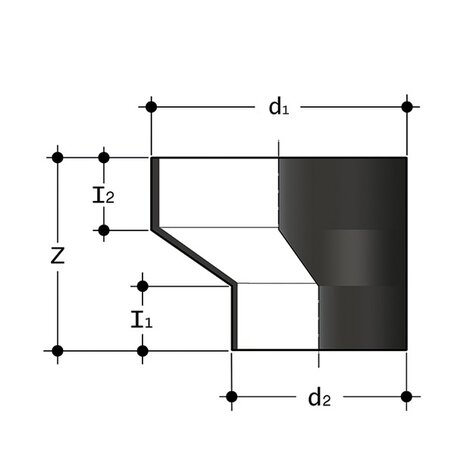

REBE SDR17 - Eccentric reducer

Eccentric reducer, short spigot, for butt welding SDR 17 - S 8.

Series of short and long fittings designed for conveying fluids under pressure for butt welding and electrofusion applications.

| Reference | d1 | d2 | Z | l2 | l1 | S1 | S2 | g |

|---|---|---|---|---|---|---|---|---|

| REBE17160090 | *160 | 90 | 140 | 54 | 40 | 9,5 | 5,4 | 700 |

| REBE17160110 | *160 | 110 | 120 | 45 | 40 | 9,5 | 6,6 | 500 |

| REBE17160125 | *160 | 125 | 110 | 44 | 40 | 9,5 | 7,4 | 400 |

| REBE17160140 | *160 | 140 | 100 | 43 | 40 | 9,5 | 8,3 | 340 |

| REBE17180110 | *180 | 110 | 140 | 54 | 40 | 10,7 | 6,6 | 1100 |

| REBE17180125 | *180 | 125 | 130 | 52 | 40 | 10,7 | 7,4 | 700 |

| REBE17180140 | *180 | 140 | 120 | 51 | 40 | 10,7 | 8,3 | 560 |

| REBE17180160 | *180 | 160 | 100 | 43 | 40 | 10,7 | 9,5 | 320 |

| REBE17200140 | *200 | 140 | 130 | 50 | 40 | 11,9 | 8,3 | 900 |

| REBE17200160 | *200 | 160 | 120 | 51 | 40 | 11,9 | 9,5 | 660 |

| REBE17200180 | *200 | 180 | 100 | 43 | 40 | 11,9 | 10,7 | 540 |

| REBE17225160 | *225 | 160 | 140 | 57 | 40 | 13,7 | 9,5 | 1200 |

| REBE17225180 | *225 | 180 | 120 | 48 | 40 | 13,4 | 10,7 | 900 |

| REBE17225200 | *225 | 200 | 100 | 40 | 40 | 13,4 | 11,9 | 700 |

| REBE17250160 | *250 | 160 | 160 | 62 | 40 | 14,8 | 9,5 | 2400 |

| REBE17250180 | *250 | 180 | 140 | 54 | 40 | 14,8 | 10,7 | 1400 |

| REBE17250200 | *250 | 200 | 133 | 55 | 40 | 14,8 | 11,9 | 1100 |

| REBE17250225 | *250 | 225 | 100 | 40 | 40 | 14,8 | 13,4 | 800 |

| REBE17280200 | *280 | 200 | 160 | 68 | 40 | 16,6 | 11,9 | 2500 |

| REBE17280225 | *280 | 225 | 130 | 52 | 40 | 16,6 | 13,4 | 2050 |

| REBE17280250 | *280 | 250 | 110 | 47 | 40 | 16,6 | 14,8 | 1700 |

| REBE17315225 | *315 | 225 | 160 | 62 | 40 | 18,7 | 13,4 | 3800 |

| REBE17315250 | *315 | 250 | 140 | 57 | 40 | 18,7 | 14,8 | 2100 |

| REBE17315280 | *315 | 280 | 120 | 54 | 40 | 18,7 | 16,6 | 1400 |

* resale products

- Size range: d 12 ÷ d 800 (mm)

- Nominal pressure: SDR 17 (PN10) with water at 20 °C, SDR 11 (PN16) with water at 20 °C

- Temperature range: -40 °C ÷ 60 °C

- Coupling standards - Reference standards:

- Welding: EN ISO 15494. Can be coupled to pipes according to EN ISO 15494

- Flanging system: ISO 7005-1, EN 1092-1, EN ISO 15494, ANSI B16.5 cl.150

- Construction criteria: UNI EN ISO 15494

- Test methods and requirements: UNI EN ISO 15494

- Installation criteria: DVS 2202-1, DVS 2207-1, UNI EN 12201- 3, UNI 10520, ISO 21307,UNI 10521, UNI EN 1555-3, ISO 4427- 3, ISO 4437-3

- Fitting material: PE-HD

- Seal material: EPDM, FKM