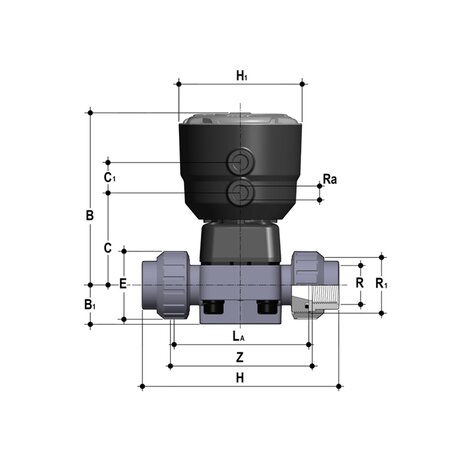

DKBUFV/CP NC - Pneumatically actuated 2-way diaphragm valve PN6 DN 15:65

Pneumatically actuated diaphragm valve with BSP threaded female union ends. Normally Closed function.

The new DKB/CP diaphragm valve is the proper solution for non-severe operating conditions that, however, require reliability and a long working life. The new internal geometry of the body optimises the fluid dynamic efficiency by increasing the flow rate and ensuring an optimum linearity of the flow adjustment curve. The DKB/CP is extremely compact and very light.

The new DKB/CP diaphragm valve has a piston actuator in PP-GR with a simplified design, ensuring essential performance.

Main features:

- Compact and light piston in PP-GR , ideal for heavy-duty applications in chemically aggressive environments with a diaphragm perimeter containment system that ensures the perfect compression of the rubber without any lateral expansion.

- Piston in high strength IXEF®. The high quality finishing of the external surface guarantees perfect slidability over the seal and ensures a long working life without any actuator maintenance.

- High strength stainless steel stem with double seal O-Ring. Floating pin connection between the actuator stem and diaphragm to prevent concentrated loads, improve the seal and extend its lifetime.

- Actuator equipped with 4 independent cartridge springs arranged radially to uniformly distribute the load on the piston.

- Dual function main gasket. Piston seal: the gasket does not move but sits securely on the actuator cylinder instead of the piston. External seal: the gasket positioned above the threaded joint between the bonnet and cylinder ensures that the coupling is not stressed by the pressure inside the actuator.

- Easy installation in confined spaces:compressed air inlets with G 1/4” threaded adjustable connections to enable alignment with the piping. PP-GR connections prevent any risk of corrosion.

- New valve body internal design. Substantially higher flow coefficient and lower pressure drops. The degree of efficiency reached has also enabled the size and weight of the valve to be reduced. Adjustment linearity: the internal profiles of the valve greatly improve its characteristic curve, allowing extremely sensitive and precise adjustment along the entire length of the shutter stroke.

| Reference | R | DN | PN | B | B1 | C | C1 | E | H | H1 | La | R1 | Ra | Z | g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DKBUFVNC012E | 1/2" | 15 | 6 | 134 | 25 | 66 | 24 | 41 | 131 | 97 | 90 | 1" | 1/4" | 97 | 685 |

| DKBUFVNC034E | 3/4" | 20 | 6 | 137 | 30 | 69 | 24 | 50 | 151 | 97 | 108 | 1"1/4 | 1/4" | 118 | 747 |

| DKBUFVNC100E | 1" | 25 | 6 | 145 | 33 | 78 | 24 | 58 | 165 | 97 | 116 | 1"1/2 | 1/4" | 127 | 975 |

| DKBUFVNC112E | 1"1/2 | 40 | 6 | 193 | 35 | 112 | 24 | 79 | 208 | 126 | 154 | 2"1/2 | 1/4" | 165 | 2722 |

| DKBUFVNC114E | 1"1/4 | 32 | 6 | 149 | 30 | 82 | 24 | 72 | 188 | 97 | 134 | 2" | 1/4" | 145 | 1101 |

| DKBUFVNC200E | 2" | 50 | 6 | 231 | 46 | 142 | 24 | 98 | 246 | 157 | 184 | 2"3/4 | 1/4" | 195 | 5984 |

- Connection system for solvent weld, threaded and flanged joints

- Optimised fluid dynamic design: maximum output flow rate thanks to the optimised efficiency of the fluid dynamics that characterise the new internal geometry of the body

- Bonnet fastening screws in Stainless Steel protected against the external environment by PE plugs. Absence of metal parts exposed to the external environment to prevent any risk of corrosion

- New flanged bodies: the new bodies, characterised by a monolithic flanged structure, are available in PVC-U, PVC-C and PP-H materials. This design, free of joints between body and flanges, considerably reduces mechanical stress and increases system performance

- CDSA seal system (Circular Diaphragm Sealing Angle) with a uniform distribution of the shutter pressure on the sealing membrane offers the following advantages:

- Operating torque reduction.

- Reduced mechanical stress on all valve components (actuator, body and diaphragm).

- Low risk of the accumulation of deposits, contamination or damage to the diaphragm due to crystallisation.

- Easy to clean valve interior

get_app

get_app